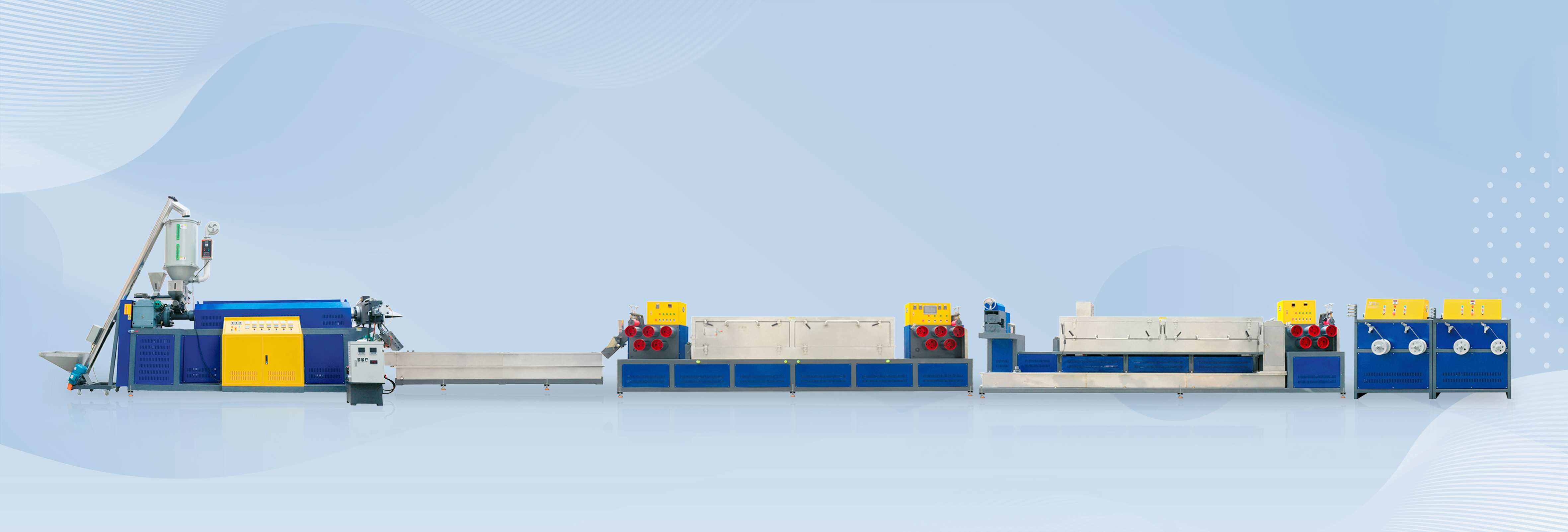

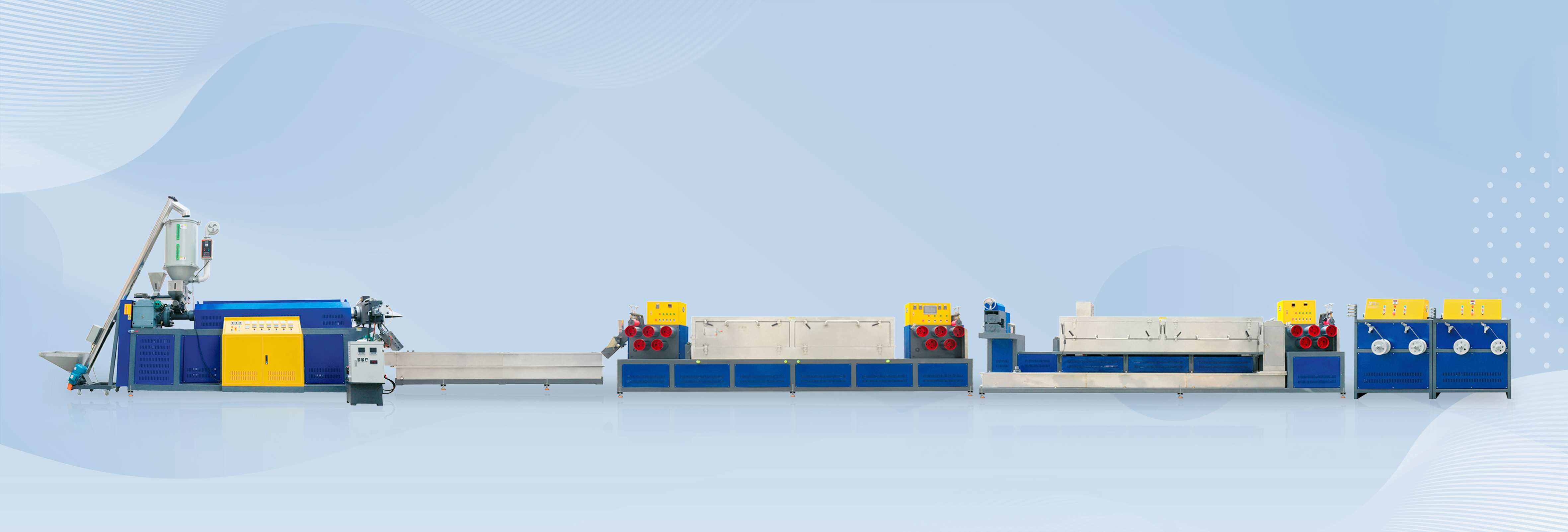

Plastic machinery 100% raw materials PP strapping production line

PP strapping equipment for automatic strapping machine using PP

strap

PP strapping equipment:

Features:

High degree of automation: reduce manual intervention, improve

efficiency, PLC control, easy debugging.

High production efficiency: continuous production, large output, 24-hour non-stop production.

Stable product quality: automated control ensures consistency of

extrusion specifications, suitable for high-end strapping machines.

Feeder---- transfer PP raw materials into the machine.

Extruder----heat and melt the PP raw materials and extrude them into shape.

Molding mold---- make the molten PP tape embryo pass through the mold to form a

strip.

Cooling water tank----cool the extruded PP tape embryo to ensure its shaping.

Tractor----pull out the cooled strapping tape to maintain a stable production

speed.

Oven---- heat the strapping tape to improve its strength and toughness.

Embossing machine---- emboss the surface of the strapping tape to increase friction and

prevent slipping.

Shaping oven----heat again, shape, and make the PP tape more standardized.

Reeler---- reel the strapping tape into rolls for easy storage and

transportation.

EXTRUSION PARAMETERS TABLE

| Model | PP-2 | PP-4 | PP-6 | PP-8 | PP-10 | PP-12 |

| Raw material | PP polypropylene new material/recycled material |

| Number of tapes | 2 | 4 | 6 | 8 | 10 | 12 |

| Width(mm) | 5-19 | 5-19 | 5-19 | 5-19 | 5-19 | 5-19 |

| Thickness(mm) | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 |

| Line speed(m/min) | ≧260-300 |

| PLC control system | PLC | PLC | PLC | PLC | PLC | PLC |

| Screw Model | 90 | 110 | 125 | 135 | 135 | 135 |

| Reducer model | 200 | 220 | 250 | 280 | 280 | 280 |

| Winding machine | Automatic winding machine /Semi-automatic winding machine |

| Screen Changer | Automatic/Manua |

| Production capacity 24H | 2.5-3T | 6-7T | 8-9T | 10-11T | 12-13T | 13--14T |

Features of embossing wheel:

1. The embossing wheel is nitrided and heat-treated to achieve a

surface hardness of 60 degrees, which is strong and durable. The

surface texture of the strapping tape pressed out by this embossing

machine is clear and rough enough, and the automatic strapping

machine uses strong belt feeding.

2. The upper and lower flower wheels of the embossing machine are

equipped with synchronous gears to ensure synchronous rotation of

the upper and lower wheels, ensuring that the flower spinning on

both sides of the strapping tape is completely consistent,

increasing the beauty and transparency of the strapping tape.

3. When assembling the upper and lower flower wheels, a fixed gap

is left to prevent collision, which extends the service life of the

flower wheels

Principle of tempering and shaping of PP strapping tape:

1. Heating treatment

• Choose the right temperature: Generally speaking, the tempering temperature of PET (polyethylene

terephthalate) strapping tape is between 180-220°C, and the

tempering temperature of PP (polypropylene) strapping tape is

between 120-160°C.

• If the temperature is too low, the internal stress cannot be

effectively eliminated; if the temperature is too high, the

strapping tape will be over-softened or even melted.

• Heating method:

• Common heating methods: hot air heating and infrared heating.

• Hot air heating heats the strapping tape by circulating hot air,

which is uniform but relatively inefficient.

• Infrared heating directly heats the strapping tape surface using

infrared radiation. The heating speed is fast, but it is necessary

to control the radiation intensity to avoid overheating of the

surface.

About After-sales

We provide comprehensive technical support and service for our PP

Strap Making Machine. Our team of experienced technicians can

provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit

drawings, etc.

2.Installation, commissioning and training of PP belt making

machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

WHY CHOOSE US

The company has more than 30 years of experience in thePP PET

strapping equipment manufacturing industry in China. It has a

professional R&D team, sales team, production plant, imported

processing equipment from Germany, and technical personnel often go

abroad for further study and learning. It has more than 50 patented

products. In the Chinese packaging industry, our company has a good

reputation, advanced technology, and high-end products, and always

ranks first. We can provide customers with better equipment and

produce higher-end products.

Suitable for strapping tools:

Semi-automatic baler.

Fully automatic baler.

High-speed baler.

Handheld baler.

Iron buckle clamp baler

FQA:

Q:What is the voltage of PP strapping equipment?

A:380V/50HZ, we support customization

Q:Can the PP strapping production equipment be customized according

to the factory length?

A:Yes, we can customize the length according to the customer's

factory size.

Q:Where is the PP strapping equipment produced?

A:We are from China.

Q:Can PP strapping equipment provide after-sales service?

A:Yes, we have professional after-sales engineers who provide

24-hour online guidance.

Q:Is the quality of PP strapping equipment stable?

A:We have 30 years of manufacturing experience, and have their own

PP packaging belt production plant, equipment quality is stable,

the process is worth choosing.

Q:Does PP strapping equipment support customization?

A:We are a manufacturing plant that can customize model size,

extrusion capacity, voltage and so on according to customer

requirements.