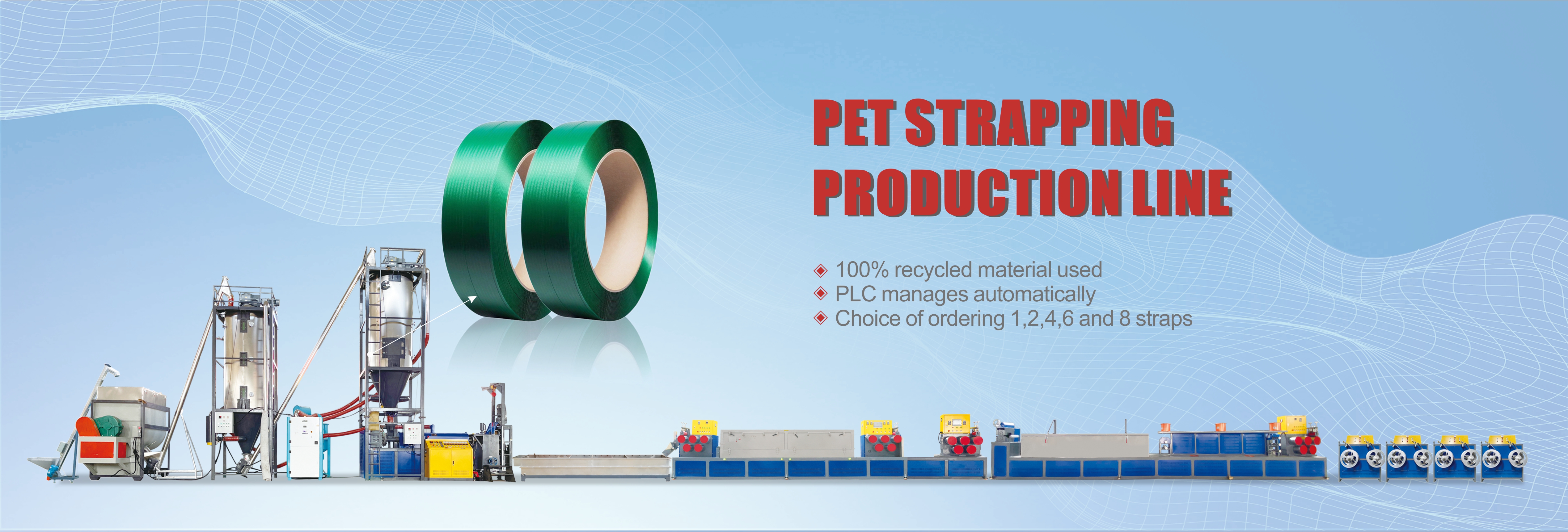

Shenzhen Jiatuo Plastic Machinery Co., Ltd, specilizing in PP & PET

Strap production and development for more than 20years.

Products consist of PET/PP Strap Making Machine, Rattan Making Machine, Handheld Strapping Machine, Plastic Coating

Machine, high-precision Plastic Embossing Roller, PP & PET Strap Winder, Tensile Testing

Machine, Strap Printing Machine, Plastic Extrusion Screen

Changer, Extrusion Machine Parts, automatic suction

machine, screw feeder, crusher, etc; Automatic wrapping machine,

automatic packing machine, automatic packing machine for all bags

and automatic packing machine; High grade, high-strength and

environment-friendly PP machine, PP packing belt, pet plastic steel

belt and other packaging materials.

The target of Jiatuo Machinery Co., Ltd. is to offer the best

quality machines to the customers from all over the world. With the

advanced technology, experienced engineers and skilled workers, we

have the capability to manufacture specific machines according to

customer's requirement.

Excellent quality and professional service is the promise made by

Jiatuo Machinery Co., Ltd. to new and old friends.

We welcome new and old customers from all walks of life to contact

us for future business relationships and achieving mutual success!