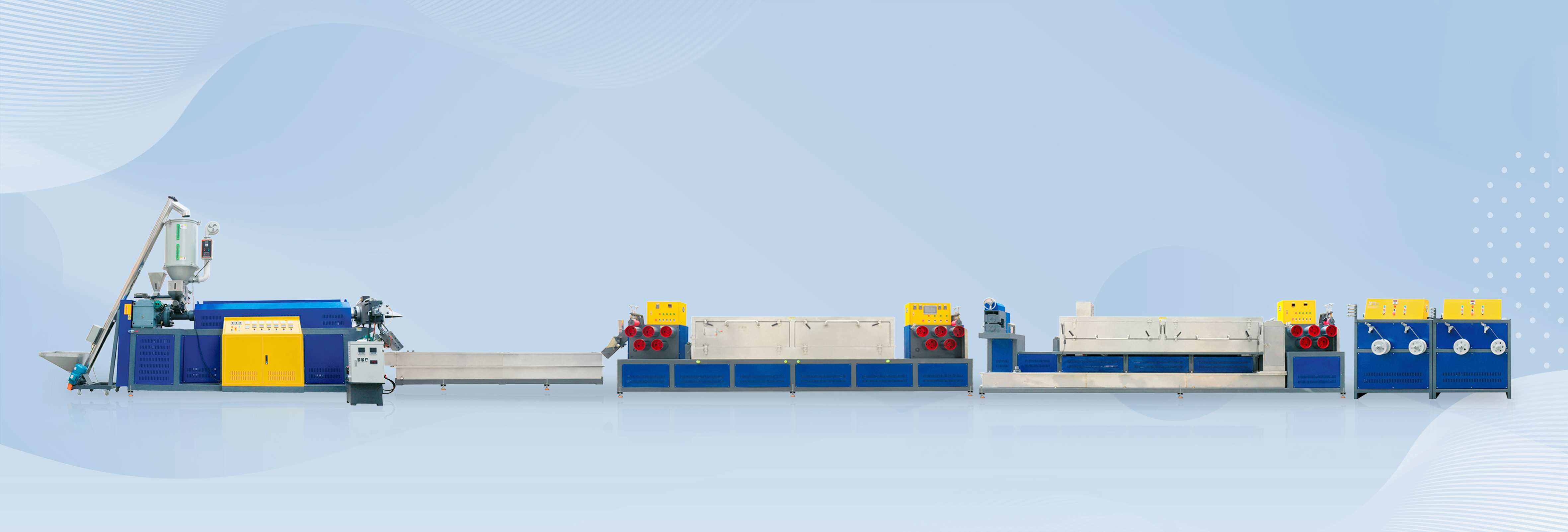

Packaging machinery Single screw PP strapping production line PP

strapping production machine with servo winding machine

PRODUCT DESCRIPTION

PP strapping tape production line is a high-end intelligent

extrusion equipment that can produce PP tape: width: 5-19mm,

thickness: 0.3-1.2mm

Raw materials-----PP strapping equipment can produce plastic raw materials:

100%recycled materials or PP polypropylene new materials to produce

strapping tape;

Screw-----The equipment adopts high-precision high-quality screws, adopts

well-known brands, and has unique parameter design. It has the

advantages of large extrusion volume, good plasticization, high

hardness and wear resistance; equipped with a quantitative

extrusion system, the width and thickness of the produced belts are

the same, the error range is small, and it meets the national

strapping tape acceptance standards;

Automatic screen changer------Equipped with a non-stop automatic screen changer, the screen does

not need to be stopped, and the efficiency is maximized. 4-net

circulation large-area filtration does not require frequent screen

changes.

EXTRUSION PARAMETERS TABLE

| Name | PP strapping production line |

| Machine size (L*W*H) mm | 3600*1200*4000 |

| Product arrange mode | PP One out four |

| Extrusion Capacit(kg/h) | 240 |

| Speed (m/min) | more than 250 |

| Number of Straps | 4 |

| PLC control system | PLC |

| Outgoing band width(mm) | 5-19 mm |

| Band Thickness(mm) | 0.4-1.2 |

| Capacity per day | 5.7-6 T |

ADVANTAGES

PP raw materials do not need to separate the dry and water

treatment . There are automatic circulation on preheating and

drying that save a large number of equipment investment and reduce

the production cost by 30%;

Utilizing the retrieving bottle slice as raw materials that

reducing the cost to a great extent;

With the multi-purpose machine, produce the PP PET straps in

different specifications directly and don not need to change the

mould head;

Comparing with new polyester slice, the transparency of products is

just the same, but the tensile strength and shock

resistance are up to the international grade;

Low Energy consumption, but high production capability;

Easy to operate, save the manpower and two persons for one

production line on average

FAQ

1. WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Shenzhen.

Machine quality and customer satisfaction is our pursuit.Be sure we

have the strength to provide you with quality machines and perfect

service.

2. WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

3. PAYMENT TERMS

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid

before delivery by T/T or irrevocable L/C by payment(at sight).

4. DELIVERY CONDITIONS

4.1 Delivery condition: FOB Shenzhen port or CIF destination Port.

4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller

should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

5. WARRANTY TERMS

5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

5.2 Seller shall grant: services and spare parts, free-of-charge service

throughout the entire equipment during warranty period.

5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts

after the 12months warranty terms.

WHY CHOOSE US

1. We major in PP & PET Strap Production Line for 20 years

2. Can use 100% recycled bottle flakes material

3. The final straps can be packed automatically

4. Always have at least 3 sets of sample machine in our workshop

5. Can take customers to see the running machines

6. Can test the machine for customers